Re:Code Labs

Re:Code Labs (Recode Labs LLC, Japan) is an engineering company specializing in PLC control, system design, and software development for manufacturing sites.

Your Engineering Partner for Reliable, On-Site Solutions

I integrate PLCs, PC software, and IoT system design to create production environments that never stop — and make the invisible visible. From control design and software development to on-site testing and commissioning, I deliver one-stop technical solutions that go beyond simple contracting, addressing the real challenges faced on the shop floor.

02.

Work Philosophy & Selected Projects

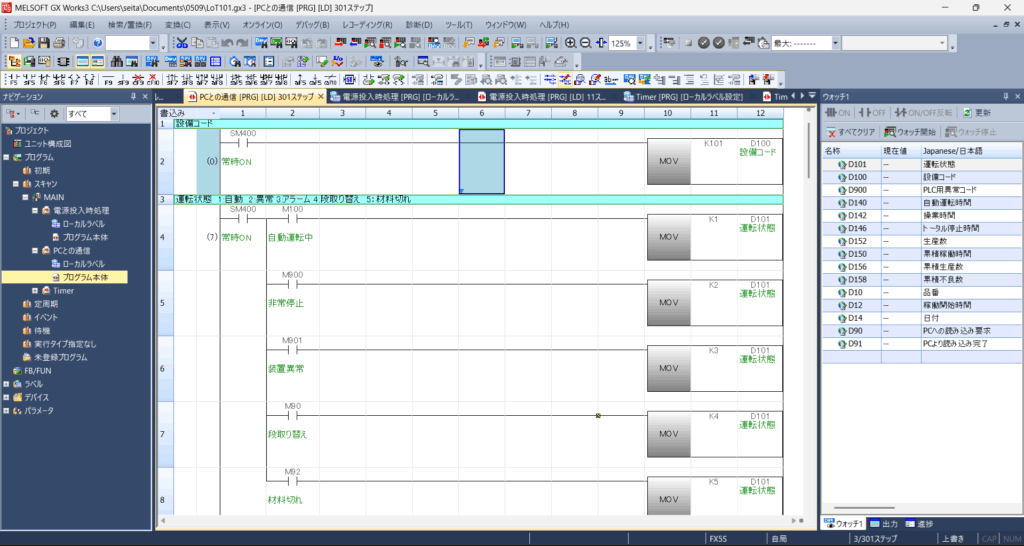

1. Flexible Ladder Logic — No Step-Ladder (SFC)

Instead, I design logic based on state relays (M devices) to manage process transitions.

This approach eliminates the need to modify multiple steps when adding or changing sequences.I avoid using the conventional step-ladder (SFC) structure for sequence control.

Instead, I design logic based on state relays (M devices) to manage process transitions.

This approach removes the need to modify multiple steps when updating or expanding sequences.

Advantages:

Example:

2. Structured Internal Relay Numbering

This keeps the logic easy to read and maintain, even after many years.

Example structure:

M300–399 : Alarms & resets

Benefits:

Easier handover between engineers

Prevents duplicate or inconsistent M-number usage

3. Logical Grouping of Timers and Interlocks

This ensures consistent timing control and easier adjustments during debugging.

Reasoning:

4. Readability and Maintainability Over Formality

I value designs that technicians can easily understand on-site, even under pressure.

Summary

Internal Logic: Numbered by function for structured readability

Timers & Interlocks: Grouped together for faster debugging

Design Priority: Field practicality and reliable operation

Tools and Experience

HMI: Mitsubishi GOT, Keyence VT

Programming Languages: Ladder Logic, Structured Text, Function Block

Additional Tools: Python (for data logging and analysis), MySQL, Google Apps Script

Engineering Expertise

With a focus on PLCs, PC software, and IoT, I support production line optimization and on-site digital transformation (DX).

By integrating control, communication, and data processing, I help realize “non-stop equipment” and “visible operations.”

1. PLC Control Design

Compatible with Mitsubishi, Keyence, and OMRON systems. Providing end-to-end support — from ladder logic design and on-site commissioning to upgrades of existing equipment.

2. Software Development

Developing data management and automation tools with VBA, Python, and Google Apps Script — including accounting systems and QR code solutions.

3. IoT & Data Integration

Integrating PLCs with cloud services, databases, and Raspberry Pi for real-time monitoring and data visualization.

4. Motion Design

Adding movement and life to ideas through animations, video graphics, and transitions that engage, inform, and delight viewers.

Let’s build something together

Share your project ideas or challenges — I’ll get back to you as soon as possible via the contact form below.