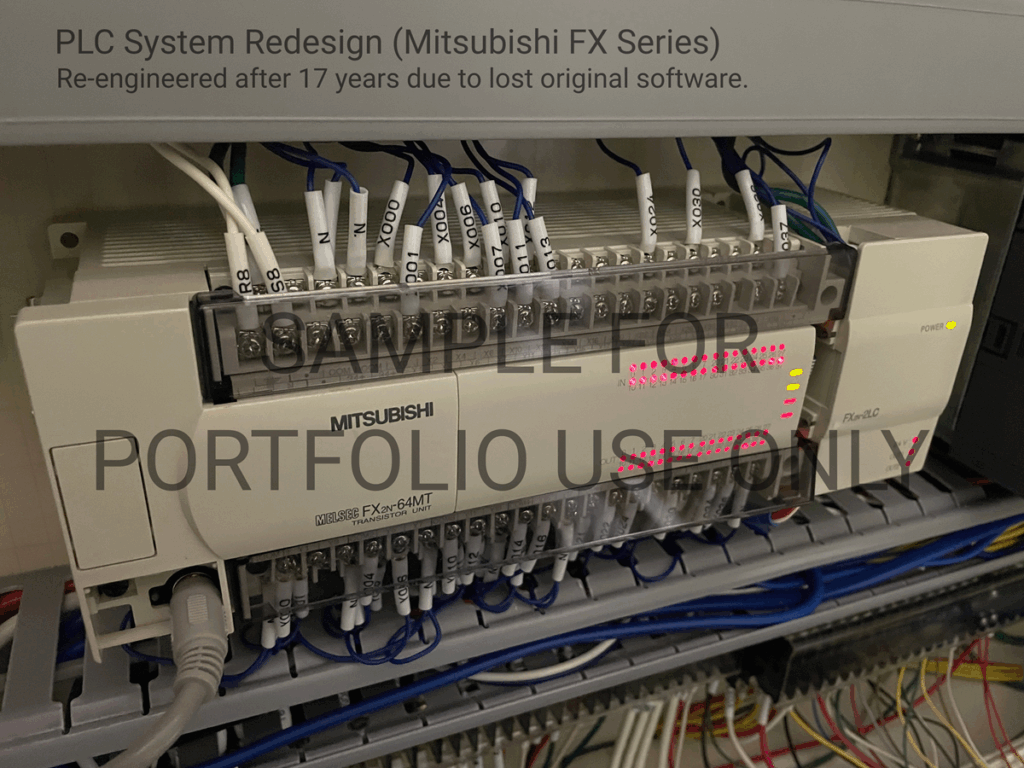

Legacy PLC Revival and Redesign (Mitsubishi FX2N + GOT1150)

This project restored a 17-year-old industrial control system whose PLC program was completely lost due to battery failure.

The original Mitsubishi FX2N unit had no available backup data, requiring a full software reconstruction from hardware signal tracing and on-site signal verification.

A new control program was designed, tested, and implemented to replicate and stabilize the original system behavior.

The operation panel was rebuilt using a Mitsubishi GOT1150 HMI for direct machine operation and monitoring, enabling intuitive control and monitoring while maintaining compatibility with the existing hardware.

This project demonstrates expertise in legacy system recovery, ladder logic reconstruction, and human–machine interface design for aging production equipment.

Control Panel Redesign & HMI Integration

The control panel was redesigned with a modular structure to simplify wiring and future maintenance.

Each component group—PLC, relays, terminals, and safety circuits—was arranged systematically by function to improve visibility and reduce troubleshooting time.

The PLC section (Mitsubishi FX2N) was reconstructed after the ladder program was lost due to battery failure.

During the restoration process, parts of the control logic were reviewed and improved to enhance operability and monitoring.

The overall layout emphasizes signal clarity, logical grouping, and sufficient space for future expansion and on-site modifications.

During the commissioning phase, the newly designed PLC program was verified through GOT1150 HMI communication.

The laptop was connected to the PLC via the HMI interface to confirm I/O mapping, monitor operation data, and ensure stable communication between devices.

This setup allowed on-site debugging and parameter adjustment without direct PLC access, improving safety and efficiency during testing.

HMI (GOT) Interface

The GOT interface was based on the original screen design, with necessary modifications applied to match the newly re-engineered PLC software.

Signal addresses, alarm links, and temperature setpoints were updated to reflect the revised control logic and ensure consistent operation across all sequences.

Although the visual layout was largely retained, internal tag mappings and diagnostics were refined to improve reliability and reduce maintenance effort.

PLC Configuration Diagram

The PLC program was designed with a parameter-based structure, allowing multiple operating modes within the same machine.

By modifying only parameter values, the system can adapt to different workpiece types, washing conditions, or inspection requirements—without changing the ladder logic itself.

This flexible design minimizes maintenance time and simplifies future customization while maintaining reliable synchronization between the master and slave PLCs.