PLC Migration Example: Mitsubishi FX3 → Siemens S7-1200

This project demonstrates the migration of an existing PLC control program from a Mitsubishi FX3 system to a Siemens S7-1200 PLC.

The original system was used in a carbonated beverage manufacturing process and included control of CO₂ filling valves, an agitation motor, and process interlocks. CO₂ concentration was measured continuously, stored in a buffer, and evaluated to calculate the mixing ratio. The process was designed to stop automatically once the target conditions were reached.

During the migration, the ladder logic was restructured to match the Siemens PLC architecture while preserving the original control behavior and operational intent. Structured Text (ST) was used where appropriate for data buffering and calculation logic.

Basic operation was verified on real hardware, including I/O behavior and control sequence validation. This project highlights practical experience in PLC program migration, cross-vendor control logic adaptation, and implementation on Siemens S7-series PLCs.

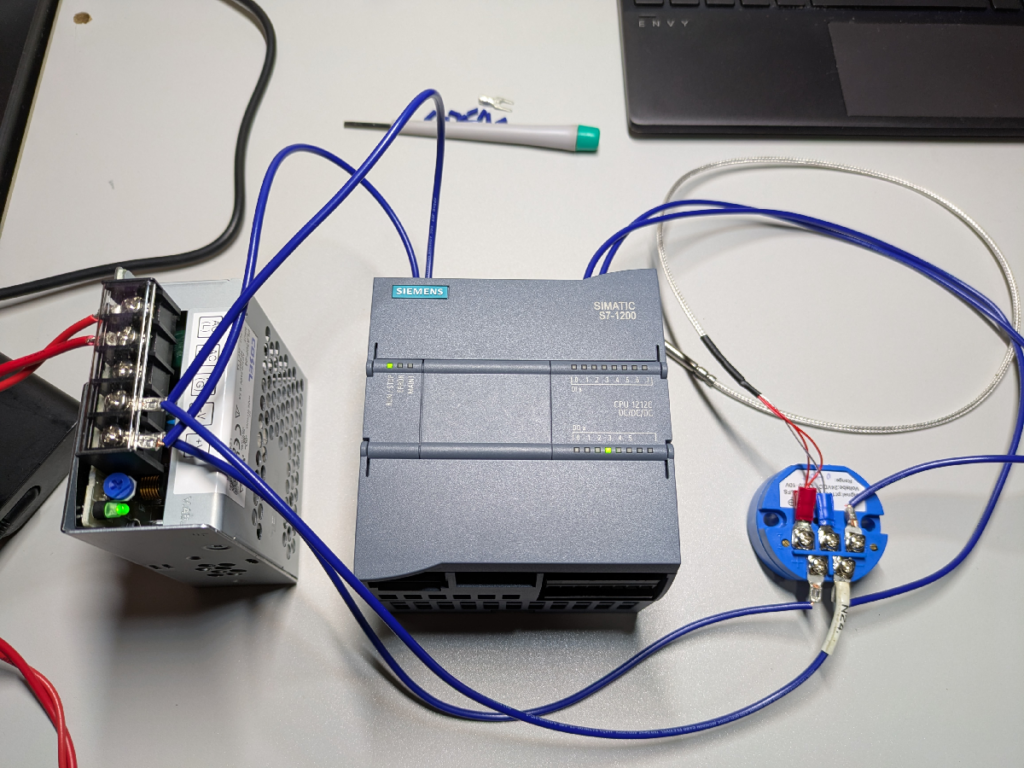

Siemens S7-1200 Analog Input Test Setup

This setup demonstrates a Siemens S7-1200 PLC configured to evaluate a PT100 temperature sensor as an analog input signal.

The PT100 sensor is connected through a signal conversion stage and treated as an analog value within the PLC program. This configuration was used to verify analog signal handling, data scaling, and integration with control logic during system testing.

Siemens Ladder Logic Implementation (TIA Portal)

This ladder logic was implemented using Siemens TIA Portal, following Siemens programming conventions and block structure.

The program demonstrates reliable adaptation to Siemens-specific ladder logic representation, symbol handling, and network organization, while maintaining clear and maintainable control logic.

Structured Text (ST) Programming for Data Processing

This Structured Text (ST) code implements data buffering and calculation logic within the Siemens S7-1200 PLC.

An array-based buffer is used to store measured values, and a loop-based calculation is applied to derive an average value for control decision-making. ST was selected to improve readability and maintainability for numerical processing that would be less clear in ladder logic.

Summary / Conclusion

This project demonstrates practical experience in PLC program migration and implementation using a Siemens S7-1200 PLC.

The original control logic was successfully adapted to the Siemens environment, including ladder logic restructuring and the use of Structured Text (ST) for data buffering and calculation tasks. Real hardware testing was performed to verify basic operation, signal handling, and control behavior.

Overall, this work highlights the ability to transition control logic between different PLC platforms, understand vendor-specific programming environments, and implement clear, maintainable control software suitable for industrial applications.