For quite some time, I had felt that the name SIEMENS simply sounded cool.

I had always wanted to work with Siemens PLCs at least once, but in Japan, it is extremely rare for clients to request Siemens equipment. Most projects rely on domestic manufacturers.

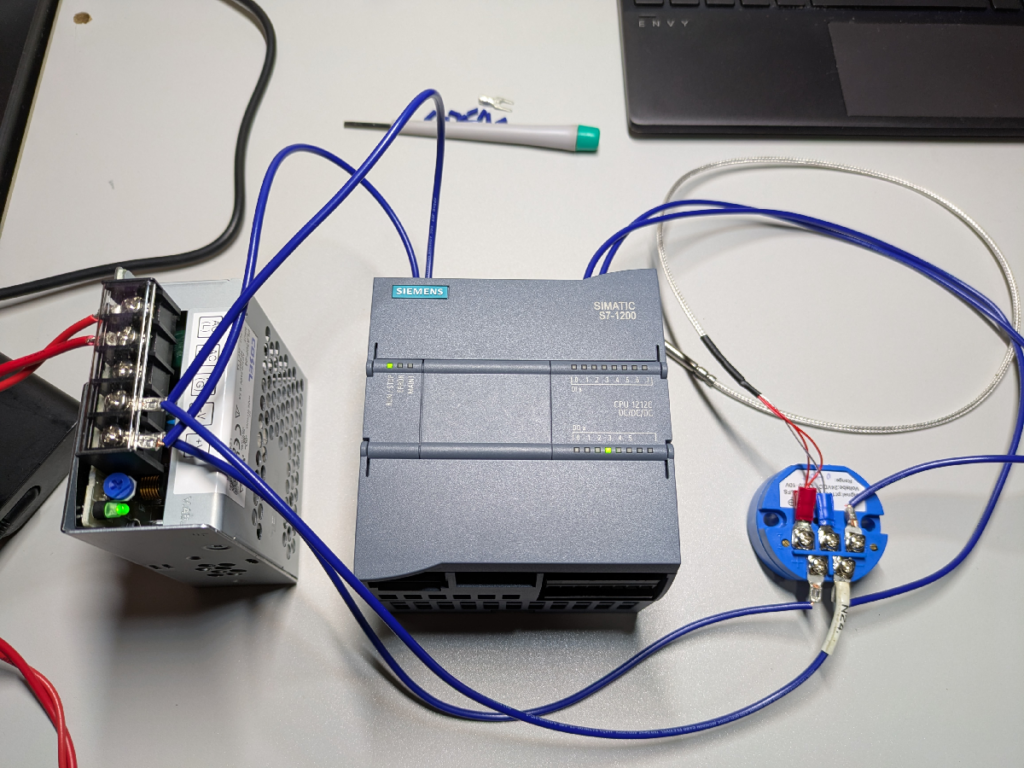

That felt a little unsatisfying to me, so during the year-end and New Year holidays, I decided to start studying Siemens on my own. I purchased an S7-1200 PLC and used it as a hands-on learning platform.

When it comes to learning ladder logic or Structured Text (ST), nothing is more effective than actually using the hardware. Last year, I had developed control software for a carbonated beverage production system using a Mitsubishi Electric PLC. This time, I decided to migrate that same system to Siemens.

The system itself is not large, but it includes analog inputs, data logging, and calculation-based control logic—exactly the kind of balanced specification that works well as a learning project. Since I already understood how the system should behave, rewriting the ladder logic and verifying identical operation helped me understand Siemens-specific characteristics much more clearly.

The engineering tool I used was TIA Portal.

The trial version is easy to find online by searching for the tool name, and it can be used without functional limitations for 21 days. One thing to note is OS compatibility: depending on the version, it may not run smoothly on Windows 11. In my case, I installed it on an older PC running Windows 10. These details vary by version, but as of January 20, 2026, the latest release appears to be TIA Portal V21.

After actually programming and testing the system, my impressions were as follows:

- Long vertical or horizontal ladder networks are not easy to manage

- The environment clearly encourages the use of FCs and FBs

- For calculations, Structured Text is far more efficient than ladder logic

- Among Japanese PLCs, the overall feel is closest to Omron

- Variable definition and handling feel simpler than Omron

- The concept of data blocks (DBs) is quite different from typical Japanese PLCs

Overall, I feel that anyone with solid control system design experience should not find Siemens PLC programming particularly difficult.

When talking with Japanese engineers, I often hear that Siemens PLCs are “hard to use,” but in my opinion, this is largely due to familiarity with Mitsubishi or Keyence systems. If you already have experience with Omron PLCs, Siemens should not be a major hurdle. Of course, there are unique characteristics, and some time is required to get used to them.

In my case, I was able to complete the ladder logic and verify correct operation without major issues. Once you get past the initial learning curve, Siemens feels like just one of many PLC platforms. Considering that Siemens reportedly holds around 30% of the global PLC market, learning it may well be a worthwhile investment for long-term work opportunities.