Work & Projects

Automotive Gear Washing & Inspection System

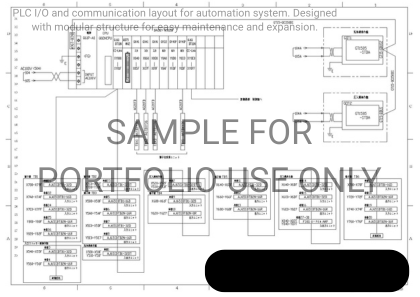

System Specifications

- PLCs: 2 units

- Communication Network: CC-Link

- HMI: 3 GOT terminals

- Heaters: 5 units

- Hydraulic Unit: 1 set

- Conveyor System: 1 set for workpiece transfer

- Washing Pumps: 4 units

- Inverter: 1 unit

- Others: Additional sensors, solenoid valves, and safety circuits

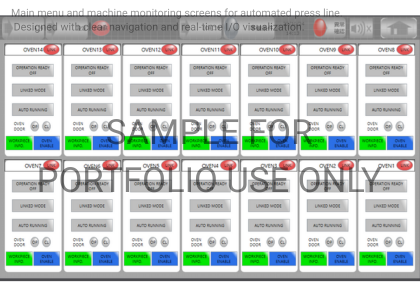

Multi-PLC Linked Control System for Industrial Ovens

System Specifications

- PLCs: 15 units (14 ovens + 1 master panel)

- Communication: Tag-based PLC networking (Omron Sysmac)

- HMI: Omron NB series, centralized operation panel

- Control Mode: Auto / Linked / Manual Monitoring:

- Real-time status for all ovens (door, enable, workpiece info)

- Language: English / Japanese dual-display support

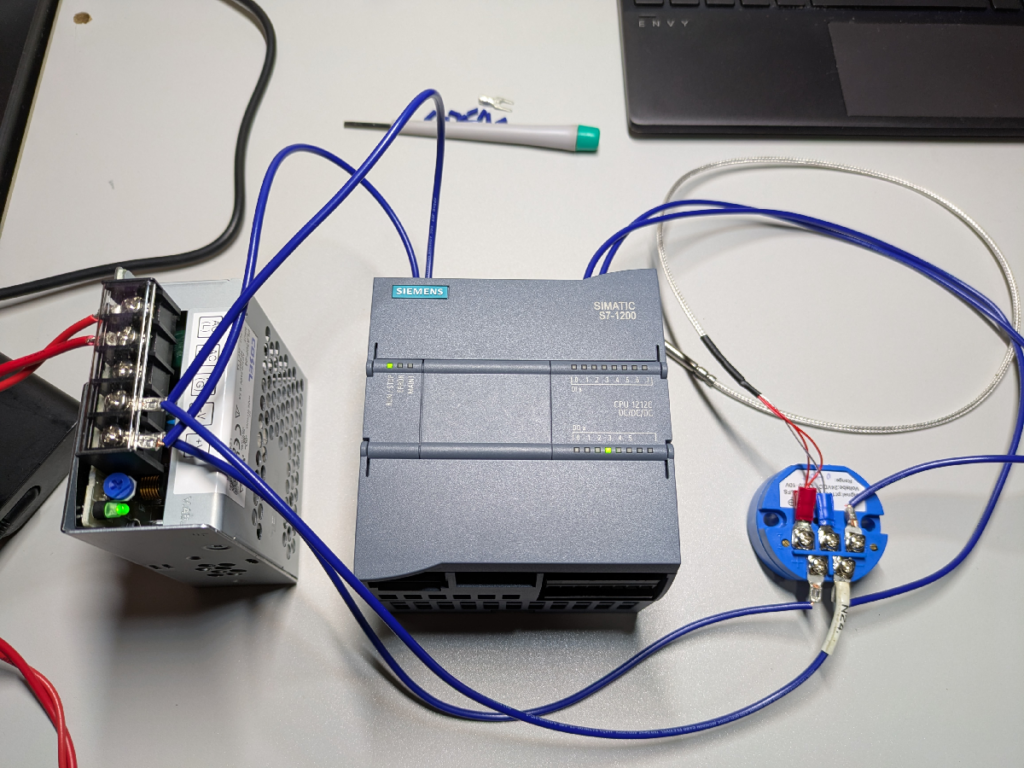

PLC Migration Example: Mitsubishi FX3 → Siemens S7-1200

This project demonstrates the migration of an existing PLC control program from a Mitsubishi FX3 system to a Siemens S7-1200 PLC.

The original system was used in a carbonated beverage manufacturing process and included control of CO₂ filling valves, an agitation motor, and process interlocks. CO₂ concentration was measured continuously, stored in a buffer, and evaluated to calculate the mixing ratio. The process was designed to stop automatically once the target conditions were reached.

During the migration, the ladder logic was restructured to match the Siemens PLC architecture while preserving the original control behavior and operational intent. Structured Text (ST) was used where appropriate for data buffering and calculation logic.

Basic operation was verified on real hardware, including I/O behavior and control sequence validation. This project highlights practical experience in PLC program migration, cross-vendor control logic adaptation, and implementation on Siemens S7-series PLCs.

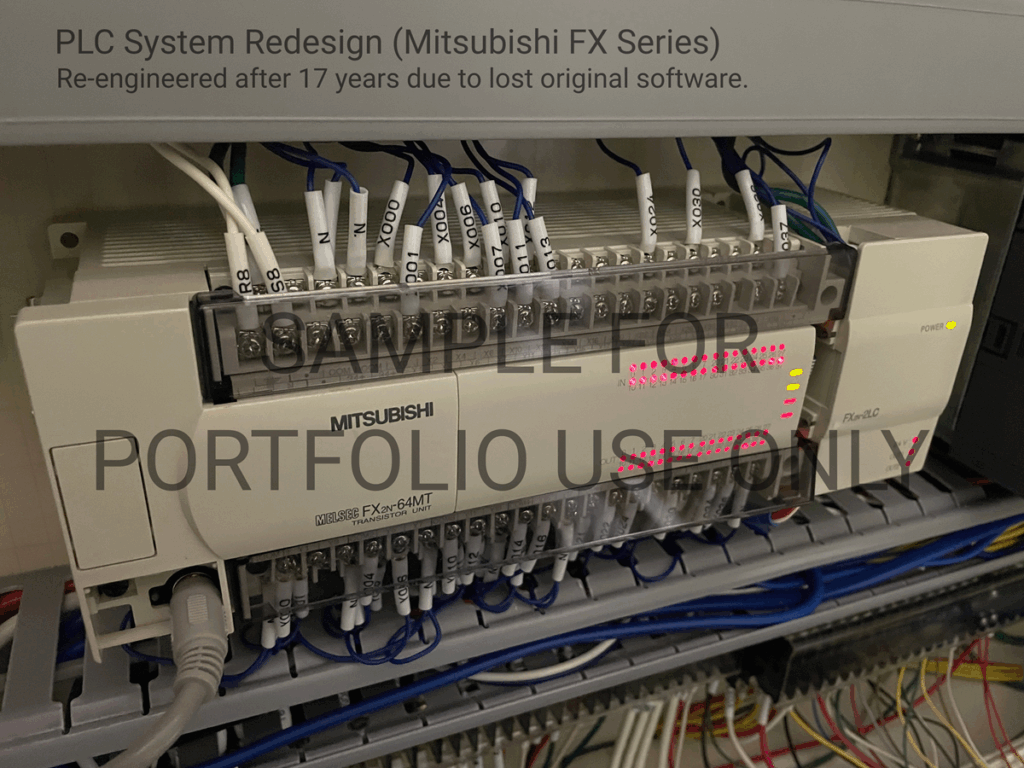

Legacy PLC Revival and Redesign (Mitsubishi FX2N + GOT1150)

This project restored a 17-year-old industrial control system whose PLC program was completely lost due to battery failure.

The original Mitsubishi FX2N unit had no available backup data, requiring a full software reconstruction from hardware signal tracing and on-site signal verification.

A new control program was designed, tested, and implemented to replicate and stabilize the original system behavior.

The operation panel was rebuilt using a Mitsubishi GOT1150 HMI for direct machine operation and monitoring, enabling intuitive control and monitoring while maintaining compatibility with the existing hardware.

This project demonstrates expertise in legacy system recovery, ladder logic reconstruction, and human–machine interface design for aging production equipment.

Let’s build something together

Share your project ideas or challenges — I’ll get back to you as soon as possible via the contact form below.